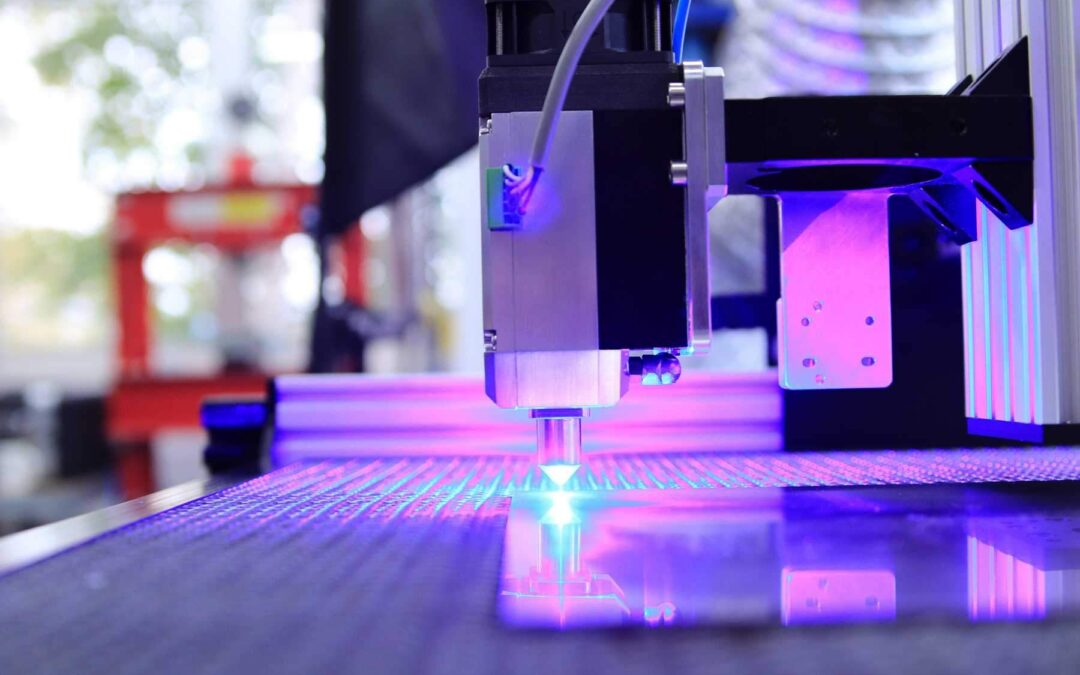

If you have ever looked at something and thought “How did they make that?” it is likely that it was designed and manufactured with CNC Technology. A CNC machine is a computer numerical control device that takes raw materials and uses a programmed pattern to develop a product. There are a number of benefits to this process as compared to traditional machine manufacturing, as mechanizing and automating the manufacturing process has already saved the global economy countless man-hours of labor. It also provides an increased level of safety for the operator of the machine. The ability to more accurately produce a higher volume of products has increased due to the ability to use CNC machines. As technology progresses, it will enable the creation of smaller, more complex, and generally more things, a process that will grow exponentially.

CNC Technology And Its Impact On Today’s Manufacturing World

Over the course of the last half-century, the adaptation of CNC technology has made a major impact on the world of manufacturing. Here are just a few examples of those changes.

Increased Scalability & Efficiency

It is impossible to measure the exact size of how much time, effort, and money has been saved by the use of CNC technology. A recent article in The Boss Magazine discusses how machines have an advantage in efficiency as compared to humans, being that they are capable of doing the same thing continuously, without requiring a break or making an error. This increased output has allowed even the smallest manufacturing firm to be able to increase their supply output, making their products available to more consumers.

Improved Quality & Accuracy

Before the adaptation of CNC technology, it was a challenge to create multiple versions of the same product, and have them be exactly the same. If this work was spread out to several different manufacturing facilities, that only further increased the chances of variance. Industry publication Computer Aided Design Guide delves further into this, explaining that the addition of CNC technology helps to ensure that each product comes out the same, as long as you use the same operation to create it. This greatly helps companies to create products at their locations around the globe, bringing merchandise to the shelves faster.

Making The Workplace Safer

The design and manufacturing of smaller parts used to be a major cause of workplace injury. Removing as much of the human element from the creation process is not just better for the bottom line, but it also ensures that your workers are not getting hurt, and therefore are capable of getting more done.

If you have an idea for a product, part, or something else you want to be made by a company here in Charlotte, then you need to be sure it can be made quickly, accurately, and affordably. Our team here at Components By Design has been using CNC technology to meet the needs of our customers for over 20 years. Give us a call at (704) 804-4899 to find out how our team can make your design dreams into something real.