If you are considering a fabrication project requiring some level of precision, you may be wondering if CNC cutting or laser cutting is the right technology for the job. Here we will break down the benefits of each technology to make an informed decision.

CNC Machining or CNC Cutting

CNC machining is a manufacturing process in which materials are cut into specific shapes and sizes using a computer-controlled machine. The CNC machine is programmed with a CAD (computer-aided design) file, which tells the machine how to cut the desired shape.

CNC machinery is a versatile technology that can be used for a variety of projects, including:

-Cutting Letters and Logos into Materials

-Cutting Custom Shapes Into Sheet Material

-Cutting or Drilling Material for a Specific Application

-Etching Text, Images, Symbols & More into Metal & Plastic Components

-Routing Out Internal Cavities

One of the benefits of CNC machining is that it can cut a wide range of materials, including wood, plastic, metal, and composites. The CNC machine can also be set up to drill holes or rout out internal cavities, making it the perfect technology for fabricating custom components.

Another benefit of CNC machining is a relatively fast and efficient process. The CNC machine can quickly cut through various materials, resulting in shorter lead times and lower costs.

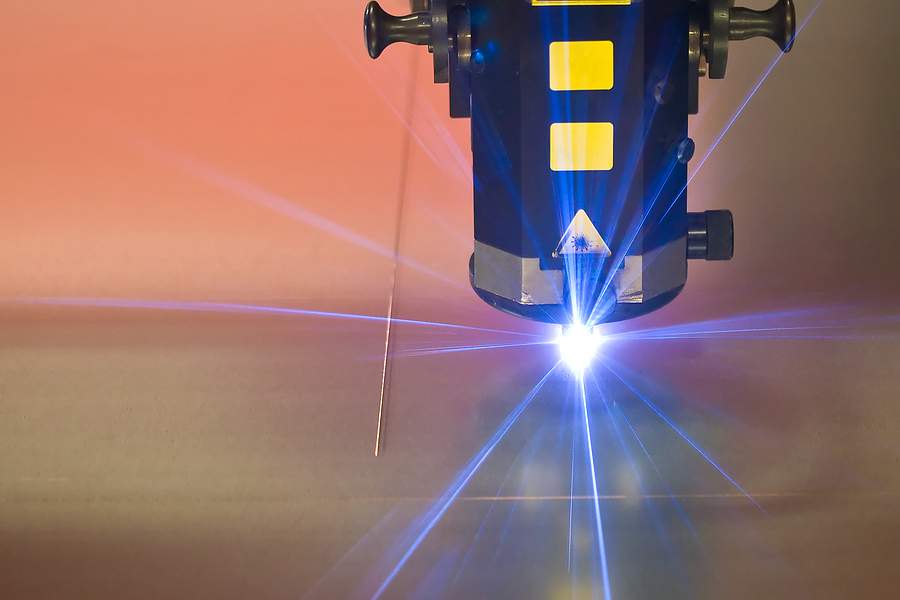

Laser Cutting

The laser cutting process is similar to CNC technology as it depends on a computer, but with laser cutting, the material is cut by a highly focused beam of light. Laser cutting is ideal for projects requiring intricate and detailed shapes as the laser can easily cut through various materials. Some benefits of laser cutting include:

-Precise and Detailed Cuts

-No Heat Affected Zone (HAZ)

-Can Cut a Variety of Materials

-Can Cut Multiple Parts at Once

One of the benefits of laser cutting is that it cuts a wide range of materials, including wood, plastic, metal, and composites. The laser beam can also be set to various depths, allowing for various cutting applications.

With precise and detailed cuts, laser beams can cut thin materials accurately.

With laser cutting, it does not produce a heat-affected zone (HAZ). The HAZ is the area above the material being cut where the temperature has been elevated due to friction from cutting through the material. This feature is beneficial because it allows the user to cut through many materials without distorting or warping the material.

The third benefit of laser cutting is that it can cut multiple objects simultaneously. The operator can set up a fixture with multiple parts and run them all at once, reducing labor costs and increasing throughput.

Which Technology Is Right For Me?

The technology you choose for your project will depend on the project’s specific needs. If you are looking for a versatile CNC technology that can be used for a variety of applications, then CNC cutting is the right choice. However, if you are looking for a technology that can cut intricate shapes into various materials, then laser cutting is the way to go.

At Components By Design, Inc. (CBD), we offer CNC cutting and outsourced CNC services

to meet the needs of our customers. We have a team of experienced professionals who can help you choose the right technology for your project and fabricate custom components that meet your exact specifications.

If you require CNC services in Charlotte, NC, please get in touch with us today.