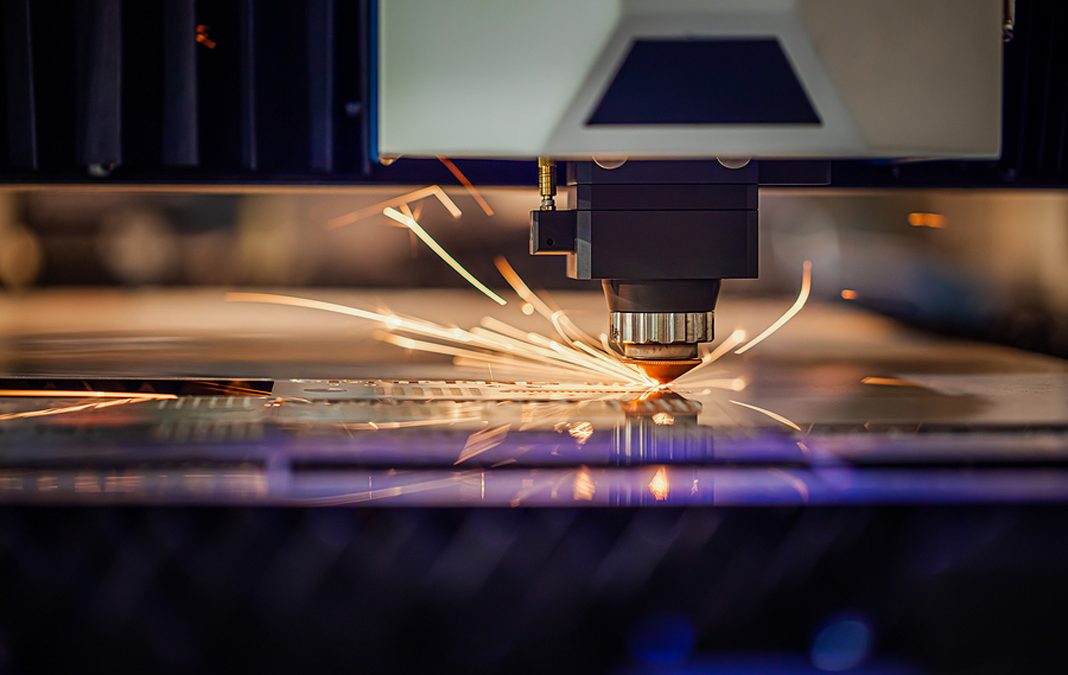

There is a heavy reliance on computer-numerical control (CNC) machinery in the manufacturing industry for operations that once required human-operated equipment like shaping machines, center lathes, routers, and vertical millers. In many cases, CNC machinery has replaced these labor-intensive operations entirely.

If you are putting together a custom project or designing a manufacturing process, you may be considering CNC machinery as an option. Here are some of the advantages of choosing CNC machinery over more traditional alternatives.

Highly Precise Components

When using conventional methods, there is always the potential for human error. But CNC practically eliminates these issues with up to 1/1000th accuracy.

Less Labor-Intensive

When you use CNC machinery, you will require fewer human hours to complete the same tasks. A single operator can run several machines simultaneously, while a traditional machine requires an engineer as well as a supervisor to ensure efficiency, safety, and accuracy.

Uniform Products

Even the best engineers using a traditional machine are likely to make a few errors. When you use a CNC machine, you get a completely uniform product instead of parts that might have slight differences or imperfections. With this option, every part is an exact match to your order and specifications.

Lower Costs

CNC machinery can run around the clock and only needs to be stopped for adjustments or maintenance. This efficiency and reduced human hours result in lower costs for your business, which you can pass along to consumers and garner your business a competitive advantage.

Safer Choice

Using CNC machinery is simply a safer alternative to other manufacturing options. While operators must still get involved, they are more distant from dangerous parts like drills, punches, and lathes that can cause serious injury and even death.

Less Maintenance

CNC machines are computer-based, and the software will update automatically as needed. The machines themselves don’t require much service, and what they do need can be completed quickly and easily.

Incredibly Versatile

CNC machining is incredibly versatile, meaning the process can produce just about any part you require for a prototype or manufacturing process.

Mass Production and Scalability

Once your specifications and design parameters are entered into the CNC machine, you can mass-produce the parts you need. Even if you start with a prototype or small production run, you have the ability to instantly scale up as needed.

Design Retention

Once you load your design into your CNC machine, you don’t have to repeat the process. When you require additional parts, the program can instantly retrieve your specifications to create what you need.

Need Help With Your Next Customer Project?

Now that you understand the advantages of CNC machinery, let us provide the expertise and service you need for your next project. Components By Design, Inc. offers a full range of CNC routing services that can help you add significant value to any project.

We have over 15 years of experience with CAD/CAM software solutions, CNC routers, and dealing with simple to complex projects. Our experience includes working with a variety of materials, including solid surface, aluminum, PVC, and acrylics. Give us a call or contact us online today to learn more about our services.