CNC Routing Creations: On Command, In Demand

- Panel Materials

- Solid Wood

- Acrylic

- Plastic

- Aluminum

- 3D Miscellaneous

- Composite Panels

- & more

If you can think it,

We can make it.

Have you ever dreamed up the perfect component, gadget, fixture, or widget but didn’t know how to make it? At Components By Design, Inc. (CBD), we make a living doing just that. We take your ideas, specs, and designs and turn them into perfectly realized pieces that are functional, accurate, and applicable to your needs.

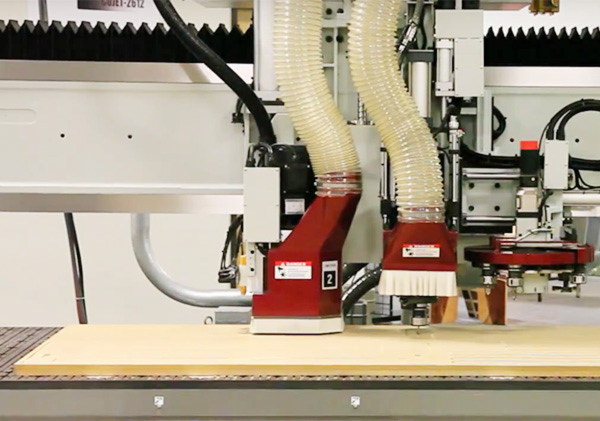

Comprehensive CNC Routing Services

Components By Design offers a complete range of CNC routing services— from simple parts and accessories to complex 3D machining. We have the technology, resources, and expertise to make it happen—so you get the end results you need without having to buy your own highly specialized, expensive equipment and machinery. But we are much more than a mere CNC router vendor.

We are a partner who believes in establishing long-lasting relationships with clients, regardless of size or industry. Your goals become our goals, and your challenges become our challenges. Our #1 objective is to find custom solutions that are efficient and cost-effective—solutions that allow your business to be productive and profitable.

“We do business with Components By Design not only because of what they do, but primarily because of who they are.”

– David Scalise, President, TileWare Products

The CBD Difference:

We will take on any project—large or small—to help you extend, evolve, upgrade, and add value to your product. The benefits of working with Components By Design are:

- Cost Savings

- Increased Capabilities

- Improved Production

- Reduced Labor Demands

- Added Capacity

- Reduced Dust Collection

- Enhanced Quality

- Upgraded Health & Safety

CBD In The News

How to Get Started with a CNC Machining Provider

Computer Numerical Control (CNC) machines are amazing! They are high-precision machine tools used in manufacturing that use pre-programmed software and codes to perform various operations. To get the benefits of CNC machining, customers need to know how to choose and...

How Fast is CNC Machining Turnaround?

CNC machining has become a major factor in manufacturing for many reasons, including the advantages of significant improvements in manufacturing production and efficiency due to CNC machining turnaround time. What is CNC Machining? Computer Numerical Control (CNC)...

The Top 13 Most Durable Manufacturing Materials

Manufacturing is a significant part of the American economy. Manufacturing industries have been called “engines of growth.” In 2023, U.S. manufacturing contributed $2.9tr to GDP, over 10% of all economic output. Manufacturing is highly diverse. Some industries, like...