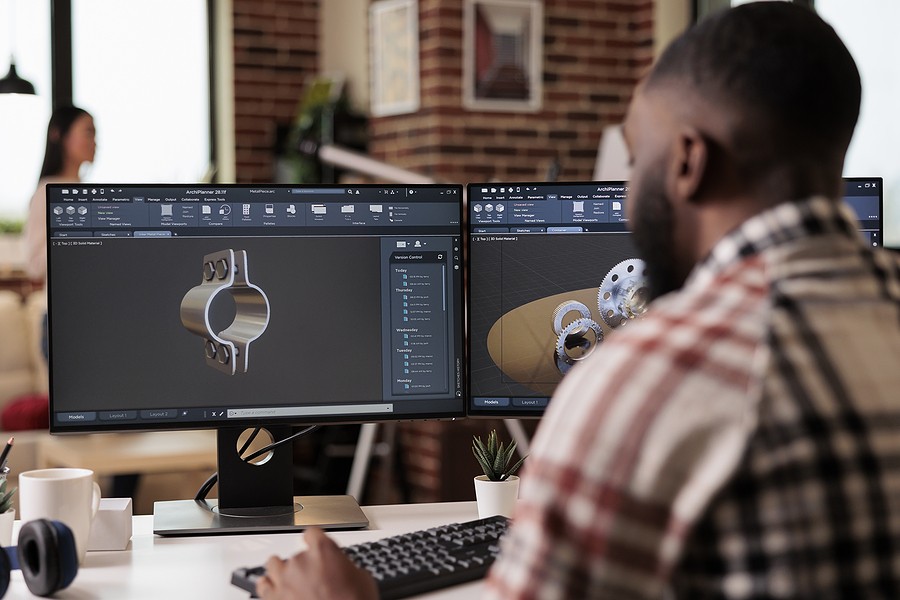

Design for Manufacturing (DFM) is an essential part of the product development process. It involves optimizing your product’s design so it is best suited for manufacturing and assembly stages. Here is why DFM is so important and some of the main principles of DFM you can apply to your processes.

Why Design for Manufacturing is Important

DFM should be applied as early as possible in the product development cycle so you can take advantage of its benefits.

- Minimize the number of product parts — You can simplify your product and reduce manufacturing costs by minimizing the number of parts through design.

- Reduce parts customization — By standardizing parts across product lines, you can improve quality and reduce costs.

- Design multi-functional parts — When certain parts, like brackets, can have different functions, it can reduce the overall number of parts.

- Design for ease of assembly — Making your product easier to assemble can reduce errors and improve overall quality.

- Design to improve compliance — This part of the process can also help your product maximize its compliance with any necessary regulations.

Five Principles of Design for Manufacturing

DFM happens before the tooling and assembly process. Committing to DFM can make the manufacture of your product less costly, complicated, and time-consuming. If you want to do Design for Manufacturing properly, the proper approach is to adhere to its five principles.

1. Process

This stage ensures that the manufacturing process itself is properly-suited to your part or product. It takes into consideration things like the parts being made, the materials used, and the complexity of the project.

2. Design

Your overall design is critical. The actual design of the product or part must align with sound manufacturing principles. If in doubt, be sure to discuss your product with your manufacturing partner.

3. Material

What materials do you plan to use? Different materials might have different tolerances or mechanical, thermal, electrical, or optical properties. Some materials will be more suited to your project than others, and some may also be more cost-effective.

4. Environment

Your product or part should be designed to stand up to the environment in which it will be used. It can look and operate perfectly in the plant, but if it doesn’t function in the real world, you haven’t designed it properly.

5. Compliance/Testing

Finally, the product you design should be tested for compliance with quality and safety standards. These might be government, industry, internal, or third-party standards, depending on your particular situation.

Get the Best Results in Your Manufacturing Design and Processes

If you are contemplating a manufacturing project or need to produce a prototype, the design phase is a vital factor in your ultimate success. One solution is to team up with a partner that can help you get everything done accurately and affordably.

Components by Design offers total CNC routing solutions and services. Through our years of experience and expertise, we offer innovative solutions to clients who need prototypes, custom components, intricate parts, and more. Contact us to learn more about how our services can transform your manufacturing business.